QualiLine-C

QualiLine-C

描述

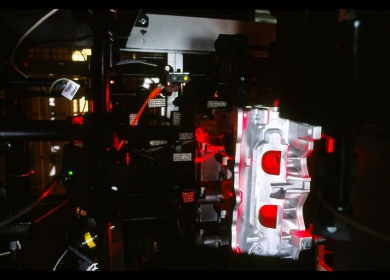

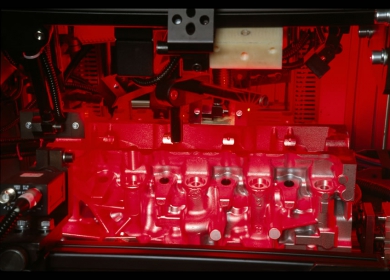

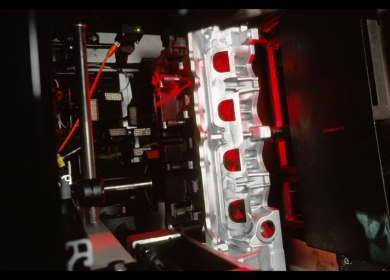

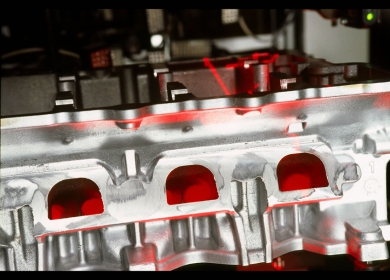

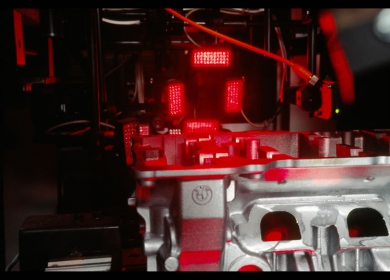

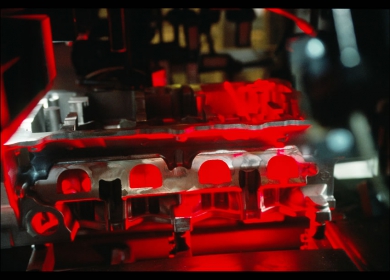

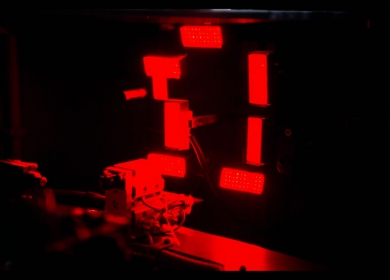

Our QualiLine-C systems have been used in production lines since 1998 providing an inline mechanical vision system for quality control systems for car factories and automotive suppliers worldwide. Having this product range we can offer a line-integrated, high-speed and high precision measurement and quality control system for cylinder heads, engine blocks and other castings.

At present, we work on the QualiLine-C Version 2.0 which will be highly modular and will contain high-tech novelties.

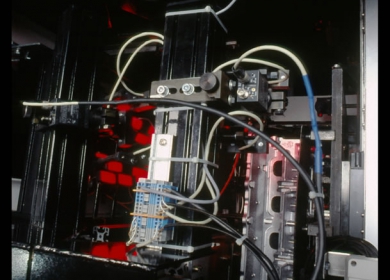

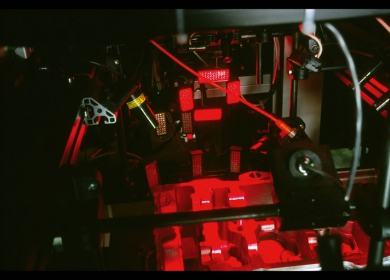

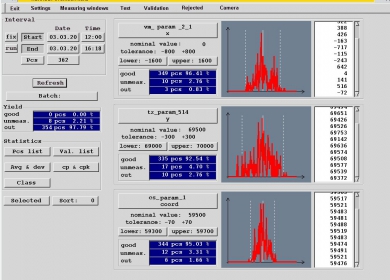

The QualiLine-C product range includes compact systems with 60-second cycle time and with just a few cameras, measurement equipment with 30-second cycle time capable of taking measurement on more than 700 geometric parameters, the flexible measurement machines utilizing robots, and finally the twin-machine construction with 12-second cycle time and more than 100 cameras for taking measurements and to check penetration through passage-ways and material porosity.

Common feature of all of our equipment, in addition to best satisfying customers' need, is accuracy and reliability. Our 100% testing solution, instead of random tests on products, got introduced upon the need raised and adopted to the cycle time of the production line. Our optical testing devices that outspeed CMM systems by multiple scales in terms of cycle times, allow the system to eliminate waste products coming out from line as well as to exclude subjectivity in qualifying processes.

应用

- Cgk and GRR-enabled measurements, according to the MSA4 standard

- Combined, flexible solutions,

the “skills” of our the stand-alone QualiLine products may be combined, as required, in the QualiLine-C system:- classic optical measurements

- 2D scanning

- 3D scanning

- measurements by robots

- surface reconstruction tests

- leakage tests

- Following production

- System support 24/7

- Provision of parts for the entire life cycle of the system

- Online diagnostics

- Remote access

- Regular trainings, updates and maintenance

应用

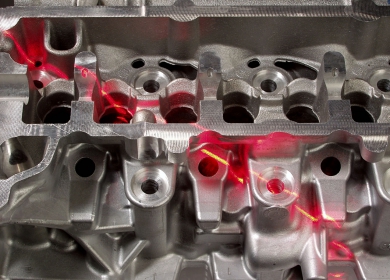

- measurement of cast surfaces

- measurement of finished surfaces

- testing the integrity of surfaces

- measurement of the position and diameter of bores

- testing the existence of bores (for a length of up to 300 mm)

- testing the existence of threads

- testing the existence of other parts (e.g. stud bolts)

- porosity and cavity test

- contour test

- testing of flatness, perpendicularity and parallelism

- leakage (e.g. water and oil space)

设备使用情况

- we have almost 40 systems operating all over the world

- in China, Russia, Hungary, Germany, Mexico

QualiLine-C 2.0 研发

This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 666774.

We developed several QualiLine-C inline casting inspection machines as turnkey systems according to market requirements. Recently, our customers' demands have been widening. They are requiring faster, simpler and more flexible measuring machines. After discussions with our customers we have come to the conclusion that the best way to increase our productivity and satisfy more customers would be to make our system modular which would help the customer to pick and choose the different inspection modules in a flexible and efficient way. This would mean we can mass produce the modules which would speed up the service and reduce the price. In addition, development of new innovative modules is also foreseen to further improve the accuracy, flexibility and to give the opportunity to inspect such geometries which were not possible in the past.

QualiLine-C 2.0 Milestones

The project started in 2015 and we have already passed few milestones:

- Market and business model testing

- Communication Plan definition

- Specification of the modules

- Modular system design

- As we are over the system design we started to work out the first modules in details. Arriving to the next milestone we will hereby inform you about it.