Quality Control

QualiLine-3D

QualiLine-3D

Description

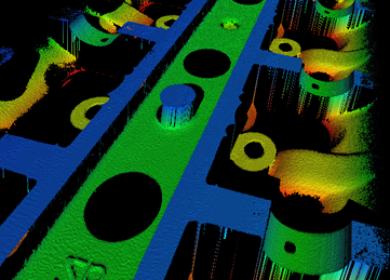

Using the QualiLine-3D system we can measure the deviation of the actual surface from the theoretical surface. This means the measurement of coordinates, the measurement of diameters, testing for the availability and lack of items, furthermore, the control of additional parameters expected by our customers. The result of the 3D scanning is a cloud of points about the scanned surface, in which we always define the distance between the scanned points, i.e. the resolution of the cloud of points according to the expectations. The processing of the scanned 3D cloud of points enables the performance of the intended geometric measurements and tests.

Features

- Cg/Cgk/R&R-enabled measurement of shape characteristics

- a resolution of up to 10 µm

- compact layout, suitable for modular integration

- shadowless full scanning of the surfaces

- automated calibration

- cycle time is adapted to the requirement

- inline and offline versions

Applications

- testing the surfaces of finished and raw castings

- testing for the existence of parts

- measurement of bore diameters

- measurement of flatness, parallelism and surface distances

Our systems in operation

- The majority of the QualiLine-C systems contain this function

- measurement of the part height of electronic products