News

strategic partnership with Cientec

We are proud to announce that we established a strategic partnership with Cientec S.A. de C.V. on the Mexican market.

Proudly celebrating more than 36 years of service to the Mexican industry, CIENTEC offer state-of-the-art technology in Quality Control equipment. The company has the most extensive line of quality test equipment in the market.

CIENTEC has become the most complete provider of physical testing instruments, a line that includes optical inspection machines, hardness testers, universal testing machines, optical emission spectrometers, manual XRF analyzer, metallographic preparation equipment and microscopes.

It also offers an extensive line of instruments for plastic/polymer testing, permeability and packaging testing equipment. Finally, it also offers salt fog chambers and environmental chambers as well as vibration testing equipment.

CIENTEC guarantees reliability and support in their products and services.

With the support of its affiliate, Sevilla Covarrubias y Asociados (SCA) that specializes in calibration and maintenance services in compliance with ISO Guide 17025, the combination of Cientec-SCA is the ideal solution for service and calibration in the field of quality control test equipment.

We look forward to working with the Cientec team.

Strategic partnership with SEBESTA

We are proud to announce that we established a strategic partnership with ŠEBESTA – služby slévárnám s.r.o. on the Czech and Slovak market.

The company ŠEBESTA was founded in 1990 and has been representing leading European suppliers of technologies and consumables for Czech and Slovak foundries for 30 years. Their portfolio includes basic consumables, tools, equipment and large technological units for both non-ferrous and ferrous metal foundries. Companies such as StrikoWestofen, ItalpresseGauss, Wollin, Indutherm, AED, Padeltherm, Lethiguel, Chem-Trend, Mammut, Schäfer Metallurgie,… are leaders in their fields with a long tradition. The strategic choice of these partners is the basis of the cooperation that ŠEBESTA managed to establish with most foundries in the Czech and Slovak Republics.

Their team consists of experts in the field of foundry technologies and in cooperation with the suppliers they look for the most suitable solutions for the Customers’ needs.

ŠEBESTA, holder of a certificate according to the ČSN EN ISO 9001 standard, provides a wide range of technological and service support and training for their products and in general on the topics of non-ferrous metallurgy, casting production technology and savings in casting production.

Our goal is to provide the best possible service on the Czech and Slovak market, by joining our forces and exploiting our strengths. ŠEBESTA will provide valuable support during installation, training, maintenance and service of the Falcon-Vision inspection machines in the local language.

We look forward to working with the ŠEBESTA team.

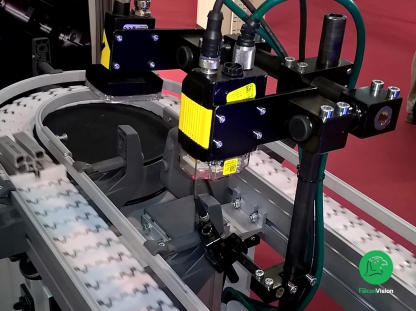

Falcon-Vision has received its first industrial order based on GasStream technology.

Last year we have submitted our proposal application directly to Brussels under Horizon 2020 Fast Track to Innovation (FTI) programme. The GasStream is a technology based on gas flow, which is constantly monitoring the interoperability of each product’s hidden channels from the production line, in a cost-effective way, not holding up the production. This allows to filter more effectively the partially or completely blocked channels in the molded parts (eg. cooling systems, cylinder heads, engine blocks). Another success can be reported: In December 2016 we received the first order for a device that is based on the internationally patented GasStream technology.

GasStream proposal

Falcon has submitted its latest proposal application directly to Brussels under Horizon 2020 Fast Track to Innovation (FTI) programme in a consortium with Nemak Wernigerode GmbH and SST Sensing Ltd. The GasStream is a technology based on gas flow, which is constantly monitoring the interoperability of each product’s hidden channels from the production line, in a cost-effective way, not holding up the production. This allows to filter more effectively the partially or completely blocked channels in the molded parts (eg. cooling systems, cylinder heads, engine blocks).